Gas condensing Boiler Ciao X 30C

Description

Wall-hung gas condensing Boiler Beretta Ciao X 30C

The new Beretta range retains the distinguishing features of its predecessor in terms of reliability and user-friendliness, while adding many important and innovative ones: from the new primary heat-exchanger in stainless steel, to the new touchpad interface up to the hydraulic DIN connections.

The new condensing range, in fact, is designed to operate with mixtures of natural gas and hydrogen - up to 20%

With CIAO X Beretta enhances the research of higher comfort and innovation in the respect of the environment, which has always represented one of the assets of the brand, since its origins. This renewed energy consciousness translates into high efficiency, low consumption and a high modulation ratio (1:8), that combined with the flexibility of installation, compact size and low weight, allow to place CIAO X at the top of its category.

But what’s more, CIAO X thinks ahead for future generations. The new range can already process a mixture of hydrogen up to 20%, the sustainable energy source that will be the real ecological turning point in the coming years.

CIAO X features a modern and linear design, which blends easily into any setting.

The compact dimensions and low weight allow the product to be easily installed anywhere, not only inside the house, but also recessed in box or outdoors, in a partially protected space. CIAO X is therefore also ideal for the replacement of old boilers, both with DIN or with Beretta connection sequence, thanks to the availability of accessory kits that simplify the conversion.

A wide range of accessories complete the offer of CIAO X: flue kit, compact water filters (softener and magnetic) and hydraulic connections cover, making installation easier and harmonising integration in both indoor and outdoor environments.

CONTROL YOUR COMFORT BY A TOUCH

One of the main distinguishing characteristics of the new CIAO X is the digital touchpad interface, combining innovative design and features with user-friendliness.

By a simple touch on 7 points of the panel, it is possible to access in an intuitive way all the settings and parameters of the boiler and the system.

Each touch activates a buzzer, that generates an acoustic feedback as a confirmation of the operation.

The LCD display communicates with the user and installer through icons, without using texts, so as to allow an immediate understanding of the displayed function.

TECHNOLOGY AND ENERGY-SAVING HAND-IN-HAND

- High modulation range: 1:8 premix modulation ratio

- Low nox: class 6 (EN 15502)

- Built-in thermoregulation with external probe available as an accessory

- Range rated certification to adapt the power of the boiler to the real thermal requests of the installation

- IPX5D electrical protection

- New flue flange featuring fast and safe quick-fastening connection and integrated flues analysis inlet

- Low energy circulator (EEI ≤ 0,20): 6 m residual head

- Hydraulic connections cover and a wide range of accessories available as optional

- Compatible with the offer of Beretta smart thermostats, both as on/off or as wi-fi thermostats in otbus communication

NEW FUNCTIONS FOR A HIGHER DHW COMFORT

In the combi models, the high-performance plate heat exchanger, developed by Beretta, connected to the primary circuit of the hot water, allows to warm up the DHW in an instantaneous way, without the need of any external tank.

The new optimized heat-exchanger has been conceived to obtain the best performance and maximum comfort for the end-user in terms of temperature stability and reduced waiting times. These pluses, which place the product at the top of its category, translate finally into respect for the environment, saving water and energy.

- PRE-HEATING AND ITS EVOLUTION INTO SMART PRE-HEATING functions have been conceived in order to further save water and gas consumption. They allow, in fact, to keep warm the water inside the new high efficiency plate heat exchanger, produced in our plants, to reduce waiting time.

- TOUCH & GO function allows to activate an instantaneous pre-heating, only for one specific request.

- Other special functions like DHW DELAY, NO-OSCILLATION PERFORMANCE, SMART FAN allow to upgrade the boiler performance in particularly difficult operation conditions like e.g. very low or very high inlet water temperature or very low water flow.

NEW CONDENSING HEAT EXCHANGER

CIAO X features a high efficiency condensing heat exchanger in stainless steel, compact and robust. It is made of a coiled smooth tube with a large section, ensuring optimized efficiency of the combustion and cleanness over time. The stainless-steel quality provides high resistance to corrosion, deriving from acid condensate. The large section of the tube and its geometry as a unique coil ensure a constant flow and prevent intrinsically from clogging. The frontal access to heat exchanger enables ease of maintenance and cleaning of the combustion chamber

LOW NOISE OPERATION

This feature makes CIAO X ideal for installation indoor, even for replacement in a kitchen.

Specifications

Seasonal space heating energy efficiency class A

Water heating energy efficiency class A

Rated heat output pnominal 24 kW

Seasonal space heating energy efficiency ŋs 93%

USEFUL HEAT OUTPUT

At rated heat output, high-temperature regime (**) P4 24,4 kW

At 30% of rated heat output and low-temperature regime (***) P1 8,2 kW

USEFUL EFFICIENCY

At rated heat output and high-temperature regime (**) ŋ4 87,6%

At 30% of rated heat output and low-temperature regime (***) ŋ1 98,2%

AUXILIARY ELECTRICITY CONSUMPTION

At full load elmax 38 W

At part load elmin 12 W

In Stand-by mode PSB 3 W

OTHER PARAMETERS

Stand-by heat losses Pstby 30 W

Annual energy consumption QHE 56 GJ

Sound power level, indoors LWA 53 dB

NOx emissions NOx 22 mg/kWh

FOR COMBINATION HEATERS

Declared load profile XL

DHW energy efficiency ŋwh 84%

Daily electricity consumption Qelec 0,152 kWh

Daily fuel consumption Qfuel 23,306 kWh

Annual electricity consumption AEC 33 kWh

Annual fuel consumption AFC 18 GJ

OTHER SPECIFICATIONS

CH heat INPUT (max-min) 25,0 - 3,95 kW

DHW heat nominal INPUT (max-min) 30,0 - 3,95 kW

Power supply voltage 230 V - 50 Hz

Degree of protection IP IPX5D

NOx class 6

CH

Max pressure-temperature bar 3-90°C

Pump: max available head (flow rate 1000 l/h) 408 mbar

Membrane expansion tank 8 liters

DHW

Max pressure 8 bar

DHW production at ΔT = 25°C / 30°C / 35°C 17,2/14,3/12,3 l/min.

DHW minimum flow rate 2 l/min

HYDRAULIC AND GAS CONNECTIONS

Inlet gas pressure (G20-G31) 20-37 mbar

CH Flow - Return / Gas inlet Ø 3/4"

DHW Inlet - Outlet / DHW tank Flow - Return Ø 1/2"

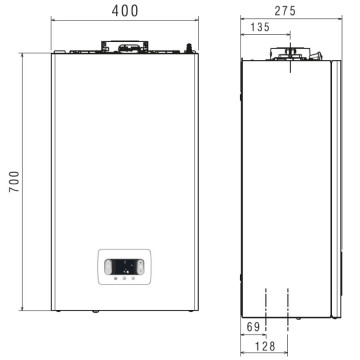

DIMENSIONS, WEIGHT

Boiler dimensions (HxWxD) 700x400x275 mm

Net weight 30 kg

FLUE OPTIONS AND LENGTHS

Max length for concentric flue (Ø 60 -100mm) 4,85 m

Max length for twin flue (Ø 80 + 80 mm) 27+27 m (B)

(*) The ‘Only heating’ models are supplied with a three-ways valve. Filling tap is not available.

(**) High-temperature regime means: 60°C Return and 80°C Flow of the boiler.

(***) Low temperature regime means for condensing boilers 30°C, for low-temperature boilers 37°C and for other heaters 50°C return temperature (at heater inlet).

(A) Up to 52+52 via twin flue adapter with air inlet swelling position (available as an accessory)

(B) Up to 45+45 via twin flue adapter with air inlet swelling position (available as an accessory)