Gas Boiler Condens 7000 WP 125

Description

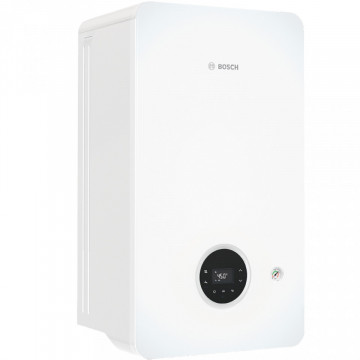

Condensing Gas wall-hung Boiler Bosch Condens 7000 WP 125 kW

Condens 7000 WP is a wall-hung boiler suitable for large domestic properties, multi-family housing and commercial installations. It can also be used in combination with high output heat pumps to create a flexible hybrid solution.

Output flexibility and compact size

An ideal choice for applications where space is restricted but there is a demand for a modern high output, high efficiency heating solution. Control strategies can provide cascade and sequencing for up to 16 boilers at a time for up to 2.2 MW of power.

High efficiency, low emissions

Our Condens 7000 WP boosts seasonal efficiencies of up to 96.5% using the much loved ALU plus heat exchanger with class 6 levels of NOx as low as 25mg/kWh @ 0% 02.

Hydrogen blend ready

Our entire gas boiler range is able to run on a 20% hydrogen blend – so your customer can be confident it will run on gas for it’s lifetime.

Precise energy management

Each boiler can automatically modulate its output to precisely match the heat demand, reducing fuel consumption and improving overall seasonal efficiency.

With cascades, modulation is from the lowest output of the smallest boiler up to the total load of all the boilers.

The 50-100kW products can modulate at a ratio of 1:5 and both the 125kW and 150kW boilers modulate at 1:6.

Time and cost saving

The boiler’s small footprint increases installation flexibility, speeds up installation time and improves access for servicing and maintenance, reducing the need to have larger boiler rooms to achieve higher system outputs.

Patented ALU-Plus heat exchanger

The maintenance-reducing heat exchanger is lightweight, robust and allows for a rapid transfer of heat. Combined with its fully insulated case, the boiler is especially quiet in the industry.

- Eye-level control – for easier commissioning

- Innovative control display – simple, self-explanatory menu guidance with

colour display and touch buttons - C8 heat exchanger – continuously optimised over the past 15 years

- Front cover – easy to remove with just one click

- Electrical connection – easily accessible from the top with reliefs for secure cables, MM100 module can be installed

- Exhaust gas connection – 100/160 as standard, rotatable by 360o, flue gas

measuring points integrated - Everything is ready – PWM cable connection for the pump group for easy connection

- Easy to assemble – simple and safe handling thanks to ergonomic handle design

Additional features and benefits

- Condensing technology with up to 108.7% net efficiency – saves fuel compared to a standard efficiency boiler

- Modulation to just 20% of total output – year round efficiency according to seasonal demand

- Cascade frame kits can be combined with site made hydraulic arrangements

- Low emission levels – cleaner combustion and increased carbon savings

- Expect to save up to 60% on the average installation time compared to GB162 V2

- Integrates with solar thermal installations – maximise savings from solar hot water

- Easy manoeuvrability with built-in handles

- Flexible control options, including Control 8000, Sense II and BMS System – increased system functionality and reduced running costs

- LPG conversion available – suitable for off mains locations.

Technical specifications GC7000WP

Nominal heat output (50/30 °C) [Pn cond] 26.2-124.5 kW

Nominal heat output (80/60 °C) [Pn] 22.3-102.6 kW

Nominal load G20, G25, G25.3 (UW) [Qn (Hi)] 24.1-118.1 1kW

Nominal load G31 (UW) [Qn (Hi)] 20.5-97.3 kW

Efficiency (37/30 °C) 30% part load cf. EN 15502 109.3 %

Efficiency (80/60 °C) at maximum efficiency 99 %

Foreseeable loss according to EN 15502. 0.12 %

Standard efficiency of the heating curve (75/60 °C) 107.2 %

Standard efficiency of the heating curve (40/30 °C) 110.4 %

Pump operating limit 2 min.

IP classification [IP rating] IP X0D

Device class according to EN 15502. B23(p), B53(p), C13(x), C33(x), C43(x), C53(x), C63(x), C83(x),

C93(x)

No. Product identification number CE-0085DL0480

Temperature classification according to EN 14471. T120

Device safety 230 V, 5AF

Mains voltage, frequency [U] 230 V, 50 Hz

Power input (without pump)

standby / part load / maximum efficiency 2 / 15 / 145 W

Maximum possible boiler installation altitude 1200 m

Permissible ambient temperature 0-40 °C

Maximum flow temperature [Tmax] 85°C

Maximum permissible water pressure [PMS] 6 bar

Maximum condensate accumulation rate 13.5 l/h

Connections

Concentric flue gas/air supply connection 110/160 mm

Heating flow/return pipe (wall-mounted gas condensing boiler) G1½"

Gas connection (wall-mounted gas condensing boiler) R1"

Condensate drain (flexible drain hose) 24 mm

Emission values according to EN 13384

CO2 content with natural gas G20, part load/maximum efficiency 8.3 / 8.9 %

CO2 content with natural gas G25, part load/maximum efficiency 6.6 / 6.9 %

CO2 content with propane G31, part load/maximum efficiency 9.5 / 10.0 %

CO, G20 outlet at maximum efficiency (n = 1) 87 ppm

Standard emission factor (EN15502) CO 40.1 mg/m3

Standard emission factor (EN15502) NOx G20 (average) 40 mg/kWh

NOx class 6

Flue mass flow rate at power nominal thermal efficiency min./max. 12.3/56.3 g/s

Flue gas temperature at 80/60 °C, part load/maximum efficiency 56 / 67 °C

Flue gas temperature at 50/30 °C, maximum 50 °C

Dimensions and weight

Height x width x length 1120 x 520 x 587 mm

Weight 97 kg

Connection set

Heating flow pipe inch G1½

Heating return pipe inch G1½

Gas supply pipe inch G 1.